An exhaust flange is a critical connection point in a vehicle’s exhaust system, acting as the metal interface that joins sections of piping to the exhaust manifold or other components. Properly welding an exhaust flange is a fundamental skill for any automotive enthusiast or professional fabricator. A successful weld ensures a leak-proof seal, maintains exhaust scavenging, and withstands the extreme temperatures and constant vibration of an operating engine.

This comprehensive guide will walk you through the entire process, from selecting the correct flange and materials to advanced welding techniques that prevent common issues like warping and cracking. By mastering these skills, you can create durable, high-performance exhaust systems that stand the test of time.

Table of Content

What is an Exhaust Flange and How Does It Work?

At its core, an exhaust flange consists of a pair of metal plates that are bolted together, compressing a gasket between them to form a tight, sealed union. This setup allows for specific sections of the exhaust system to be disconnected for maintenance, repair, or replacement without needing to cut out entire pipe sections.

The most common types are:

- V-Band Flanges: A popular alternative that uses a single clamp for a 360-degree seal, often without a gasket.

- 2-Bolt and 3-Bolt Flanges: These are the standard for most automotive applications. It’s recommended to use an M10 bolt with 2-bolt flanges and an M8 bolt with the 3-bolt option, with a tensile grade of 8.8 or higher to withstand tightening without breaking.

Table: Exhaust Flange vs. V-Band Flange

Choosing the Right Flange and Materials

Selecting the appropriate flange is the first step toward a successful weld. Your choice will impact the system’s longevity, performance, and ease of installation.

Material Compatibility: The flange material should match or be compatible with the exhaust pipe material to ensure a strong weld and prevent galvanic corrosion. Common choices include:

- Mild Steel: A cost-effective option for standard, low-budget builds.

- Stainless Steel: Offers excellent resistance to corrosion and heat, making it ideal for performance and street applications.

- Titanium: The ultimate choice for high-performance and racing applications. Titanium can endure temperatures up to 600°C (1112°F) without losing strength and offers an exceptional strength-to-weight ratio.

Size and Pressure Rating: The flange must match the outer diameter of your exhaust pipe. Furthermore, consider the pressure and temperature demands of your specific application to ensure the flange’s design can handle the operating conditions.

Preparing for the Weld

Proper preparation is arguably the most critical phase and directly determines the quality of the final weld.

- Fit-Up and Alignment: The connection between the pipe and flange must be gap-free. A poor fit-up is a primary cause of “blow-through,” where the welding arc melts through the metal uncontrollably . Hold the assembled joint up to a light source; if you see any light peeking through, you need to refine the fit-up.

- Joint Design: The best practice for a strong, flow-through connection is to use a flange with a through-hole that matches the pipe’s inner diameter closely. The pipe is shaped to fit this hole and inserted flush with the flange’s face, creating a smooth internal transition that minimizes exhaust turbulence.

- Back Purging: When welding stainless steel, back purging is essential. This process involves flooding the inside of the pipe with an inert gas like argon to prevent “sugaring”—the formation of rough, black oxides on the backside of the weld. This oxidation weakens the weld and disrupts exhaust flow . If you lack a back purging setup, products like Solarflux, a paste applied to the weld’s backside, can serve as an effective alternative to prevent sugaring.

Welding Techniques: A Step-by-Step Guide

To achieve a strong, leak-free, and visually appealing weld, follow this structured approach.

Step 1: Secure Tack Welding

Begin by applying tack welds every 20-30mm around the circumference of the flange. These small, temporary welds hold the assembly in perfect alignment for the final welding and help distribute heat more evenly, reducing the risk of distortion.

Step 2: Manage Heat with Stitch Welding

Instead of welding the entire circumference in one continuous pass, use a stitch welding technique. Weld a small section (e.g., 10-15mm), then stop and move to a section on the opposite side of the flange . A common method is to weld in quarters: start at the 6 o’clock position, weld to 9 o’clock, then jump to 12 o’clock and weld to 3 o’clock. This allows heat to dissipate evenly, preventing the flange from warping.

Pro Tip for Maximum Heat Control: For critical applications, bolt the flange you are welding to another sacrificial flange or a thick metal plate. This acts as a massive heat sink, drawing heat away from the weld zone and dramatically reducing warping.

Step 3: Execute the Weld

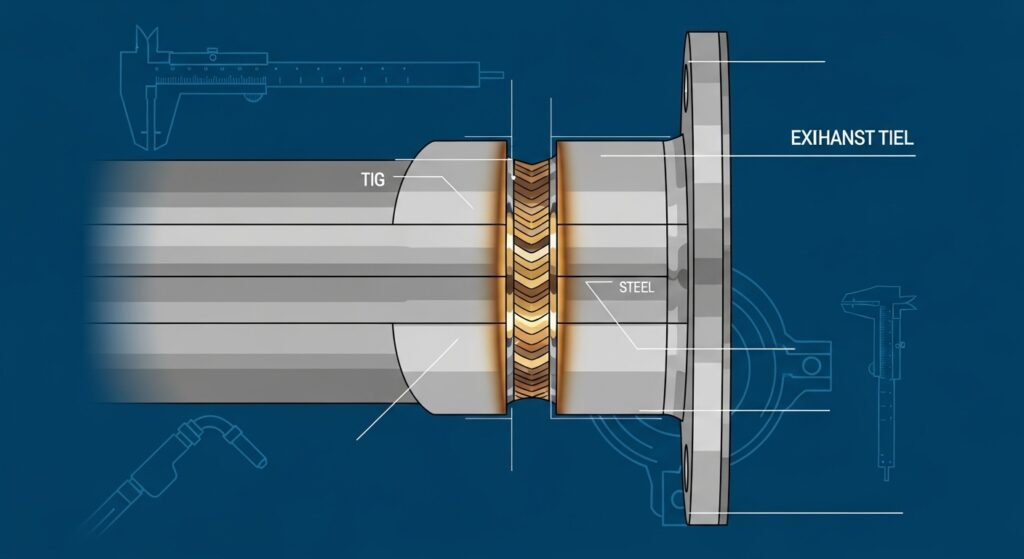

- TIG Welding: This is the preferred method for exhaust work, offering superior control and clean results. Use a 0.030-inch diameter filler rod appropriate for your base metals (e.g., 308 rod for 304 stainless, 347 for 321 stainless) . The key is to “be cool and go slow”—avoid excessive amperage, which leads to heat buildup, dark, discolored welds, and warping.

- MIG Welding: A viable and faster alternative, especially for thicker materials. When MIG welding, focus the heat on the flange and allow it to “wash over” to the pipe to avoid burn-through.

Step 4: Post-Weld Inspection and Cleaning

After welding, allow the assembly to cool naturally. Inspect the weld bead for defects like “undercuts”—small ravines along the edge of the weld that act as stress risers and can lead to cracking . These are often caused by welding too fast or using incorrect torch angle. Finally, clean the weld with a wire brush to remove any discoloration or slag.

Note: Check out our comprehensive guide on How to Weld a Flange to a Pipe.

Advanced Professional Technique: Silicone Bronze Welding

For an even more resilient joint at the exhaust port, a technique favored in top-level motorsports like NASCAR involves a combination of steel welding and brazing. The pipe is first welded to the flange from the head-side using a standard steel filler rod to ensure a strong, full-penetration weld . Then, on the backside of the flange, the joint is finished using a silicone bronze filler rod .

This method offers three key advantages:

- The lower brazing temperature minimizes the risk of burn-through on thin tubing.

- The bronze weld is more flexible and better at absorbing engine and chassis vibration, reducing the likelihood of fatigue cracks.

- It provides a smooth, golden finish that adds a touch of professional detail.

Frequently Asked Questions (FAQs)

1. Why did my welds crack on my exhaust headers?

Cracking is often due to “undercuts” in the weld bead or stress risers from a poor transition between the pipe and flange . Using a technique that allows for a smoother internal transition and a more flexible joint, like the silicone bronze method, can significantly reduce cracking.

2. Can I weld an exhaust flange without back purging?

Yes, but for stainless steel, the inside of the weld will likely “sugar” and be weakened. If you cannot back purge, use an anti-oxidizing paste like Solarflux on the backside of the weld to achieve a clean root pass.

3. My flange warped during welding. What did I do wrong?

Warping is caused by concentrated heat input. To prevent it, always use the stitch welding technique and bolt the flange to a heat sink. Avoid running a continuous bead around the flange in one direction.

4. What’s the best way to ensure a leak-proof seal?

Beyond a good weld, the seal depends on the flange faces remaining flat and parallel. Using a high-temperature gasket and proper, evenly torqued bolts is essential. The welding techniques described above are designed to keep the flange flat for optimal sealing.

5. Is it okay to remove flanges and weld the exhaust into one piece?

While possible, this makes future maintenance or repairs extremely difficult, as the entire system may need to be cut out. Flanges are included for serviceability.

6. TIG vs. MIG for exhaust flanges: which is better?

TIG welding is generally preferred for its precision and clean results on thin materials. However, MIG welding is a capable and faster process, especially for those more proficient with it.

Conclusion

Welding an exhaust flange perfectly is a blend of art, science, and meticulous preparation. By choosing the right materials, mastering fit-up, and applying controlled welding techniques like stitch welding and heat sinking, you can create durable, professional-grade exhaust connections that are free from leaks and cracks. Remember the core principles: prioritize a perfect fit-up, manage your heat input meticulously, and don’t rush the process. Whether you’re building a new header or repairing a old exhaust, these practices will ensure your fabrication stands up to the demands of the road and the track.